Connecting Geometrica: ISO 9001 Certification With a Wiki

Gerardo Méndez, quality manager at Geometrica, wrote to tell me about the company’s effort to use a wiki to document their new quality management system.

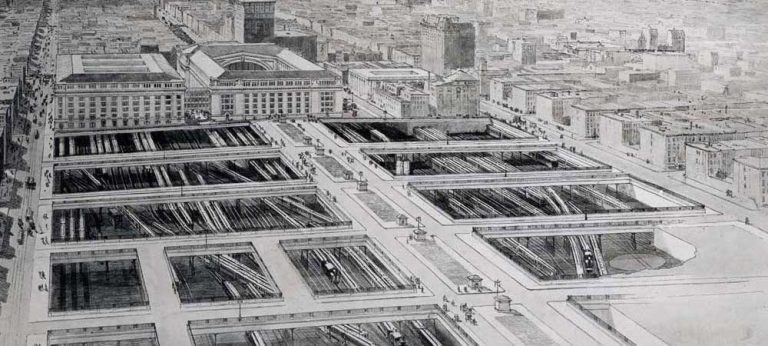

Geometrica designs, manufactures, and installs domes and space frame structures for sports venues, environmental protection, houses of worship, industrial plants, and educational assembly halls. The company is based in Houston, Texas & Monterrey, Mexico, and has delivered domes on every continent (map).

Gerardo included an excellent case study, and gave me permission to reprint it here. I’ve split it into three parts to be published over the next several days. Part 1 looks at how the company decided to use a wiki, Part 2 shows how the wiki was introduced to employees and teams, and Part 3 (below) shows how the wiki helped Geometrica achieve ISO 9001 Certification. The complete case study is also available on Geometrica’s web site. – Stewart

The approach of using a wiki to document a Quality Management System (QMS) may seem overwhelmingly obvious in a year or so, yet we are far from that today. Chances are you’ve used Wikipedia on the web, but you may not appreciate the power that a wiki can bring to virtually every facet of documentation and management systems. This case study describes how Geometrica used a wiki to document its QMS and achieve ISO 9001 certification in “record” time while avoiding the bureaucracy that often plagues this process. Just remember — You read it here first!

The Problem

Documenting a QMS is an intense process for every organization, and Geometrica’s case was no exception. Geometrica engineers, manufactures and builds domes and space frame structures around the world, and although we were confident of our quality control procedures, our clients were increasingly insistent on ISO 9001 certification. Our policies and procedures were already documented in various electronic and hard-copy formats, but these documents had been developed unsystematically to respond to problems, client demands, and training needs. There was no single approach or cohesive structure.

The company’s first approach to documentation followed the old paradigm: Once the decision was made to pursue registration, a quality committee was formed comprised of the CEO, the Vice-President, the heads of operating departments, the quality manager, plus an external consultant. The plan was to proceed in a sequential manner: vision, mission, general production system, quality objectives, organization, and formal documentation procedures, followed by process descriptions, procedures and work instructions, all in the common ISO 9001 framework.

As we emailed back and forth word-processed drafts, edits, comments, discussions, agreements, disagreements, meeting minutes, etc., it quickly became apparent that the procedure was horrendously inefficient — and the job momentous. The process itself was a big part of the problem: conflicts between documents, typos, clarifications and the organization of the information required substantial editing even for documents that had been “completed”. Meetings dragged on to resolve often small wording differences. In many cases, desirable edits would not be done because of the difficulties of keeping track of the latest version of a document while more than one person worked on it, or simply because of the effort required to update everyone’s binder. We attempted to solve the problem by maintaining only a single copy of the documents on the server and in hard copy, but even these were hard to keep in sync.

In short, the letter and spirit of ISO 9001 — enabling a management system — was lost in the in-box. At this point, we started looking at wikis.

What’s a wiki?

In specific terms, a wiki is a special website where anyone can edit the content, and where every change is saved. A wiki’s advantages stem from key paradigm shifts:

- Wiki documentation can be developed, corrected and improved while working on the processes described, as well as beforehand or after flaws are found. This helps achieve congruence between the system and everyday activities, allowing documentation to remain continually fresh.

- A wiki is a collaborative environment that empowers everyone to take ownership of the process being described, the documentation being developed, and the continuous improvement that is the goal of all quality systems. People new to wikis worry that their use will lead to chaos and poor documents, but the fact is that everyone wants to be at their best when their work is on display company-wide.

- A wiki is fun to use and fosters teamwork.

Here’s what you lose when you move to a wiki: outdated procedures pasted on walls, updates in emails, endless meetings, employee manuals that are never really up-to-date, document control hassles, and document non-conformities.

What you gain is a system centered in the organization as a whole, not in a person or department. The whole organization can provide feedback and shape the documentation to balance personal belief or subjectivity. Documentation becomes what the organization needs — not what one individual or department believes to be the best.

Meister’s brief but accurate description of a wiki is that it’s fast (1), a good fit for Geometrica, where change, teamwork, efficiency and effectiveness are key values. Upper management expected Geometrica’s ISO certification to happen swiftly without slowing the work for our clients, and a wiki made it possible.

There are many wiki engines. The most well-known is MediaWiki, which powers Wikipedia. But at Geometrica, we used ProjectForum for its ease of installation, maintenance and use.

Implementation

There was some initial resistance among the quality committee to using a wiki: worries about vandalism, poor editing and lack of control. Other objections came from ingrained perceptions about the necessity for sequential authoring-editing-approval-publication, and from the perception that when a document is published, its information is correct, complete, permanent and authoritative.

The wiki destroyed these objections quickly.

The committee empowered all its members, and later the whole company, to edit any document. The distinction between author and editor disappeared, as changes to documents appeared immediately in all company locations, including our headquarters in Houston, the plant and offices in Monterrey, and jobsites as far away as Spain and the UAE. The quality of the information improved and continues to improve with most edits, for many reasons:

- Ease of access means that users check the wiki frequently to learn more or verify their knowledge.

- More people get involved with much less effort. In the “old way”, either non-core people aren’t involved, or, if they are involved they spend lots of time in QA process meetings that mostly don’t relate to their work — a huge waste of time. A wiki allows non-core people to pay attention to just the bits they care about. Now multiply that time saving by the number of people in the organization!

- Ease of editing simplifies “minor” corrections and improvements that might otherwise be ignored because the errors were “tolerable”. The people who know a topic detect shortcomings and correct them immediately.

- The aggregation of many small corrections and improvements results in very significant changes: “wiki magic”.

- Information is not repeated. The ability to include and link to other wiki pages allows information to be maintained in a single location. Note, however, that this requires careful oversight of the system (informally known as “wiki gnoming”) as there is no built-in mechanism to avoid repetition of information.

- Incentives prompt positive cooperation of wiki users:

- Every user works for Geometrica and is identified by name and password.

- All changes to the wiki, as well as authors and times, are logged. The information is available to all through a page-history link, and to the administrator by user or date.

- Changes to any, or all documents may be monitored by any user through email or Real Simple Syndication (RSS).

- One rule: no rules. Anyone can share ideas, discuss, comment, change, edit, copy and paste as needed, since all the organization is working towards one goal. Everyone’s skills and knowledge are welcomed.

- Reverting to prior versions of a document is easy and quick.

- Having managers from different areas working together on wiki documentation created a multidisciplinary approach that enhanced learning and interaction throughout the organization.

- In our implementation, we utilized a database of “bugs” and “corrective actions” based on the open-source “Bugzilla” software (2). Originally developed to debug software, we found it ideal for debugging documents, complementing the wiki. Bugzilla helps capture the knowledge of individuals who would not normally contribute to the wiki, either because they do not use computers in their job, or because they don’t feel sufficiently confident about a certain change to make it directly on the wiki. Those individuals use the database to report bugs, which are then automatically assigned to department heads. The department heads then moderate structured, asynchronous discussions when required, discover root causes, and implement corrective and/or preventive actions right on the system (Per ISO 9001 Section 8.5.), but with hot-links to the affected documents for quick verification and audit.

In less than one year, the Geometrica QMS wiki has amassed 1577 pages of high-quality documentation containing over 3GB of data. Pages have been edited an average of 12 times, with 12 pages being edited more than 100 times. Thirty-six individuals have contributed to the QMS wiki, with the average having contributed more than 400 edits.

Example: Geometrica Continuous Improvement

The wiki process is best illustrated with an example, and the history of our “Continuous Improvement” procedure serves this purpose (in a pleasantly recursive way). The following images are not intended to be readable, but show how the form and length of the procedure change through time and wiki magic. A wiki page for this procedure was created on May 21, 2008. On June 15, it had been edited a total of 15 times, and by October 8, 30 times. Then there was a furious spurt: 112 edits in the next 8 weeks, for a total of 142 edits. Since that time, the page has been edited less than once per week.

Achieving ISO Certification

The central function of our wiki implementation was the ISO 9001 quality system. Once we shifted the documentation process to the wiki, it took nine months to complete the project. The following areas of ISO 9001 compliance illustrate the great value of the wiki approach:

The central function of our wiki implementation was the ISO 9001 quality system. Once we shifted the documentation process to the wiki, it took nine months to complete the project. The following areas of ISO 9001 compliance illustrate the great value of the wiki approach:

- 4.2.1. Documentation of the quality system. The wiki allows all documents to be stored in a place where everyone can view and review them.

- 4.2.3. Control of documents. The procedure states that documents are updated when needed, and the wiki sends an email notification to the quality committee and anyone who subscribes whenever a page is updated. The wiki ensures that current revisions are identified because it allows all versions, with date and author, to be stored and shown when needed. The wiki keeps all documents in the point of use and also stores all data in a legible and identifiable way.

- 4.2.4. Records can be easily controlled, stored, retrieved, retained — and there is no need to dispose of them. Typing information directly into the wiki’s pages (or scanning and uploading it) saves space and archives information in such an easy-to-find manner that there’s no point in printing or copying. Even though anyone can access and modify wiki information, records are safe because prior versions are automatically stored for at least six months.

- 5. Management responsibility involves several steps, on which a wiki can help focus:

- 5.1. a) The wiki allows management to communicate customer, statutory and regulatory requirements throughout the whole organization very quickly. As soon as the manager finishes typing, the wiki sends out email notifications of change to everyone who needs to know. This enhances customer focus, because customer demands are immediately cascaded to the correct organizational levels (5.2).

- 5.3. d) The wiki communicates policy to the members of the organization, as well as allowing anyone within it to check or change it. Thus the wiki promotes reviews and continuing suitability (point e).

- 5.4.2. The wiki helps maintain the integrity of the quality management system. In a paper-based system, all documents would have to be revised to ensure that a change in one is reflected in another. The wiki does this job automatically.

- 5.5.1. The wiki helps ensure that all responsibilities are communicated. Posting an organizational chart in the wiki allows instant access to roles and responsibilities.

- 5.5.3. In an era of “opened doors”, a wiki is an invaluable tool because it can perform internal communication at its best.

- 5.6. The wiki simplifies and enhances management review. The standard requires inputs to be presented, outputs to be derived and both to be recorded. Here’s how we accomplish this with a wiki:

- Prepare the review on the wiki, posting all inputs (and their graphs) in the wiki, as well as the order of the day.

- During the meeting, take notes and post them beneath the graph pictures in the page described as the “register” for the meeting.

- Record the number and comments for each corrective action reported.

- Post a small summary of findings at the end.

- Scan and post signed attendance sheet.

- 6.2.2. All competence reviews, from employee evaluations to their comparison with needed competences, can be recorded in the wiki and isolated in a page protected by password-access (for confidential information). Employee activities and allotted times can be also maintained in this area. Records of all grades in training classes can be maintained here, which makes planning for follow-up courses very easy.

- 7.3. The wiki helps manage design development planning, inputs, outputs, review, verification and validation, as well as change control. Using the wiki, a team can brainstorm ideas, process information, review output, and present feedback for verification and validation. Now a process that previously might have been reviewed by only one or two people can be reviewed and commented upon by the whole team, with no need to pass papers or send personal emails.

- 7.5.1. The wiki helps control production. Using the wiki, all registers and work instructions can be carried out online, updated easily, and printed (if needed) in the production plant. There are no worries about copies unless it’s a copy being used in the plant. A list of places where documents are posted can allow the owner of a document to eliminate previous revisions and post new ones.

- 8.2.2. The wiki simplifies internal audits. In a wiki you can plan audits, fill in the forms, print them, sign them and scan the document, all in a matter of minutes. The wiki eliminates the need to print a document, write comments on it, clean it up, type it again and print it out again. The wiki also stores signed audits; it’s easy to keep all records in one cyber-place where everyone can access them through their computers.

- 8.5. The wiki promotes continuous improvement, including both corrective and preventive actions. The combination of Bugzilla and wiki allows Geometrica to pinpoint areas for improvement, especially in documents. As a result, improvements take place almost instantaneously, since any mistake caught by a user can be reported and corrected. Any change initiates an immediate email to the person responsible for the document, alerting him or her of the change.

The Consultant’s point of view

Management Systems such as ISO 9001, ISO 14001 and OHSAS 18001 require documentation, but it has never been their intention to imply uniformity in structure and practices. Organizations are free to decide the content, extent, and detail of their documentation.

Documentation should be considered as a tool, a means to achieve a higher purpose. Many organizations make a common mistake and pay more attention to a document’s format than they do to its content and purpose. They may buy expensive document-control software with a “built in” QMS Manual, including flow diagrams, procedure pages, and work instruction templates — but this type of software tends to have very little flexibility. The software automatically sends e-mails to all involved personnel when a document is changed and often adds bureaucratic barriers such as requests for authorization to publish a new version of the document. Such methods introduce friction and are almost as slow as using hard copies.

This is where a wiki for document control — editing, sharing, recording changes, etc. — is the best solution. Even better, a wiki allows changes to be made in real time, so continual improvement never has had to wait.

Conclusion

The need for this new paradigm is a primal concern. The world is so different from that in which quality systems evolved decades ago. Today we exist as a global village: We rely on cheap transportation and effective supply chains rather than economies of scale. We cross the world in hours and close business deals from China to Chile in seconds. Networks and telecommunications tie it all together. Isn’t it the natural next step to base our quality systems precisely on these technologies?

The need for this new paradigm is a primal concern. The world is so different from that in which quality systems evolved decades ago. Today we exist as a global village: We rely on cheap transportation and effective supply chains rather than economies of scale. We cross the world in hours and close business deals from China to Chile in seconds. Networks and telecommunications tie it all together. Isn’t it the natural next step to base our quality systems precisely on these technologies?

The bottom line is that a wiki simplifies compliance with ISO 9001 by embracing collaboration and maintaining well organized documentation, the basis of knowledge management. All of the know-how of the organization resides in a media where it is stored, improved, protected from vandalism — and can be used in education and training. With the benefits that wiki technology provides, it is only a matter of time before Quality and Management practitioners change their paradigms to follow this new trend.

Geometrica had its ISO 9001-2008 certification audit in early February, 2009, and obtained its certification through BSI.

Oh, and this article was written on the wiki too.

Image © Copyright 2008 Geometrica.